GPR Scanning in Jacksonville. Reducing Risk Before You Break Ground

Jacksonville is growing from Downtown and the Southbank to JAXPORT, the First Coast logistics corridor, and hospital campuses along the Beaches. With so much construction and renovation happening near live utilities and active facilities, guessing what is inside the slab or under the surface is not an option. GPR scanning gives project teams the visibility they need to plan safe cuts, accurate cores, and clean excavations before work begins.

What GPR Scanning Finds

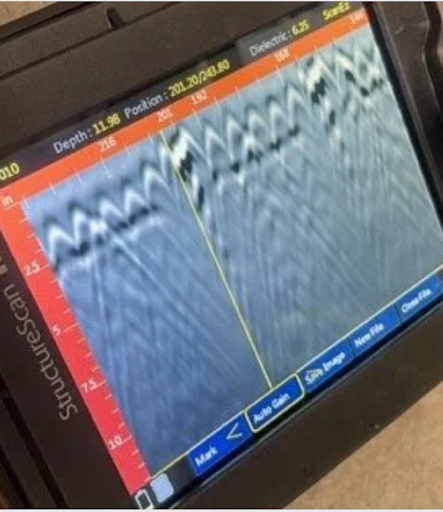

Ground Penetrating Radar uses radio waves to create a subsurface map in real time. In concrete, it helps locate rebar, post-tension cables, electrical conduit, and embedded steel. In soils, it can identify utilities, trench lines, voids, and changes in soil conditions. The output is a clear picture of where it is safe to cut or drill and where to avoid. That picture prevents accidents, protects people, and keeps your schedule intact.

Typical Use Cases

Contractors call for GPR before slab sawing, core drilling, or selective demolition inside hospitals, labs, schools, and office towers. It is also used to validate trench routes in warehouses and manufacturing plants near the airport and along the First Coast Expressway. On public works and transportation projects, scanning helps confirm panel thickness, dowel locations, and utility depth before a weekend closure. Across these settings, the goal is the same. Reduce surprises and cut cleanly without collateral damage.

Accuracy Considerations

GPR is highly effective when operators account for slab thickness, moisture, and reinforcement density. In thick or congested slabs, signal interpretation matters. Experienced crews use multiple passes, cross lines, and varied antenna frequencies to confirm readings. When needed, findings can be paired with limited exploratory coring to validate depths and materials. The result is a practical level of certainty that lets you proceed without guesswork.

Planning for Interiors

Live interiors demand low disruption. Hospitals, universities, and corporate offices expect clean work zones and predictable timelines. GPR helps create that predictability. By identifying safe routes for cores and cuts before mobilization, you reduce changes in the field and limit noise and dust duration. Pair scanning with a clear housekeeping plan, negative air when required, and tight protection of finishes to keep tenants and patients comfortable.

What You Receive

You get clearly marked surfaces, photo documentation if requested, and a brief summary of findings that identifies safe areas and conflict zones. This documentation supports your toolbox talks and helps align subs on the day’s plan. If your scope shifts, scan updates are quick and can be done in tandem with the layout, so production keeps moving.

What are the benefits of using GPR Technology?

GPR is safe around sensitive equipment

GPR uses low-power radio waves that are safe in typical environments. For hospitals and labs, the team will coordinate with facility staff and follow site-specific protocols.

GPR can see every conduit

GPR is highly effective, but results vary with depth, moisture, and materials. Skilled operators use cross passes and frequency adjustments to improve clarity and may recommend limited verification if something is unclear.It keeps the project on schedule

Most interior rooms, corridors, or equipment pads can be scanned within normal prep windows so cutting and coring stay on schedule.You can see through a variety of finishes

Most surface finishes are not a problem. The technician will advise if a small access area helps with signal quality.

Why Jacksonville Projects Benefit

Jacksonville construction often happens in complex settings. Port facilities run around the clock. Healthcare and university buildings stay occupied during renovations. Distribution hubs near I-95 and I-295 cannot afford downtime. Many of these sites have decades of add-ons and undocumented changes. GPR scanning brings clarity to that hidden history, so your plan reflects the actual conditions, not just what is on an old drawing.

How the Process Works

A trained technician walks the area with a compact GPR unit and marks findings directly on the surface. The markings translate into a plan that shows safe zones, keep out zones, and depths. If the environment is sensitive, markings can be done on protective coverings or transferred to layout drawings. The field team then coordinates with your superintendent to sequence the cutting or drilling in a way that avoids conflict and supports the day’s production goals.

Safety And Compliance

GPR scanning supports a safety-first culture. Avoiding a severed conduit or a post-tension strike is not only about cost. It is about keeping people out of harm’s way and maintaining compliance with site rules and regulations. Jacksonville sites often combine public access, busy loading areas, and security requirements. Scanning allows crews to work with confidence, set accurate barricades, and keep the area organized and safe.

Cost and Schedule Impact

Damage to utilities or post-tension can stop a job for days and trigger expensive repairs, change orders, and incident reviews. GPR scanning is a small cost compared to those delays. The value is measured in uninterrupted schedules, clean inspections, and a superintendent who can move confidently to the next task without firefighting.

When To Scan

Scan when drawings are missing or outdated. Scan when you suspect post tension, dense reinforcement, or embedded conduit. Scan before any high-consequence cut or core where a strike would create safety or schedule risk. In practice, that means scanning is part of the standard pre-task plan for interior coring, equipment pad modifications, MEP route openings, and selective demolition in occupied buildings.

Why Choose a Local Jacksonville Team

Local experience matters. A Jacksonville-focused crew understands the realities of JEA utility corridors, port security, and healthcare infection control. They know how to work around tight schedules, coordinate with facility teams, and document findings in a way your inspectors and owners will accept. That familiarity shortens the learning curve and reduces friction on site.

Trust Sterling For GPR Scanning in Jacksonville

If you need GPR scanning in Jacksonville, share your drawings and scope, plus any schedule constraints. A short scan before you cut, core, or excavate can prevent costly damage and downtime. Get a clear picture of what is inside so your team can move forward with confidence.

Planning for Industrial and Port Work

Industrial floors and port facilities bring heavy loads, embedded steel, and overlapping utilities. Scanning maps out reinforcement patterns and utility conflicts so saw cuts and cores keep structural integrity intact. That mapping also helps sequence work in tight windows, such as night shifts at terminals or short closures in cold storage operations, where every minute counts.